|

Ningbo Huaping Metalwork Co., Ltd.

|

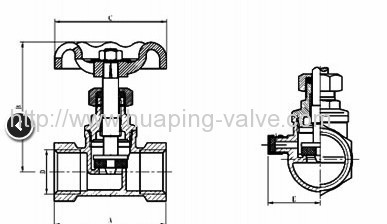

Forged Brass Body Stop Valves

| Payment Terms: | T/T |

| Place of Origin: | Zhejiang, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

• Drain Port Allows Draining of the Non-Pressure Side of the Valve When Closed

• Threaded ends comply with ANSI B1.20.1

Product Name:Brass Stop and Waste Valves

Model No.: 224w

•Brass Stop & Waste Valve, Threaded

Features:

· Threaded - Forged Brass Body - Cast Iron Handle

· 125 PSI WOG to 100°F, Maximun Temperature 180°F

· Drain Port Allows Draining of the Non-Pressure Side of the Valve When Closed

· Threaded ends comply with ANSI B1.20.1

Material List

Item | Part | Material |

1 | Body | Brass |

2 | Gasket | NBR |

3 | Stem | Brass |

4 | End Cap | Brass |

5 | Packing Nut | Brass |

6 | Packing | PTFE |

7 | Handle | Steel |

8 | Nameplate | Aluminum |

9 | Handle Nut | Steel |

10 | Seal | PTFE |

11 | Coupling Nut | Brass |

12 | Ring | Brass |

13 | Drainable Nut | |

14 | Rubber Seat | NBR |

Dimension:

224W | |||||

Size | A | B | C | D | E |

1/2" | 2.067 | 2.461 | 2.114 | 0.720 | 0.787 |

3/4" | 2.126 | 2.480 | 2.114 | 0.931 | 0.906 |

Material Control

• Sampling inspection is performed towards each batch of material,using ARL spectrum analyzer.

Machining Quality Control

• Self-check in machining process includes 1st article inspection and in-process inspetion(record the data of product every hour).

• Quality inspector performs several time?stour inspection and record the result as well.

In-coming Materials Inspection

• All components made in-house or outsourced are inspected before coming into components warehouse.